The Role of Burners in Hot Air Balloon Performance

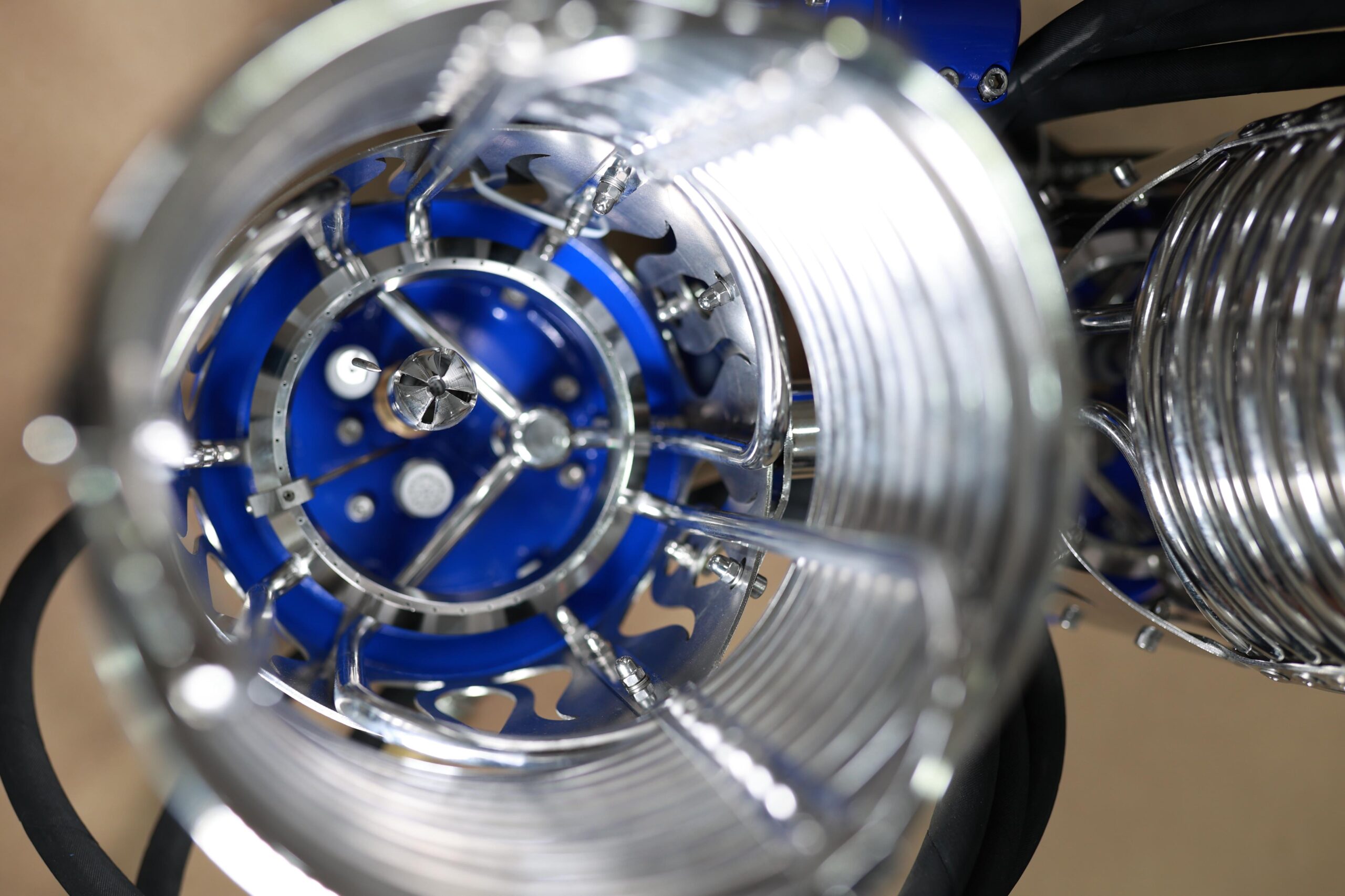

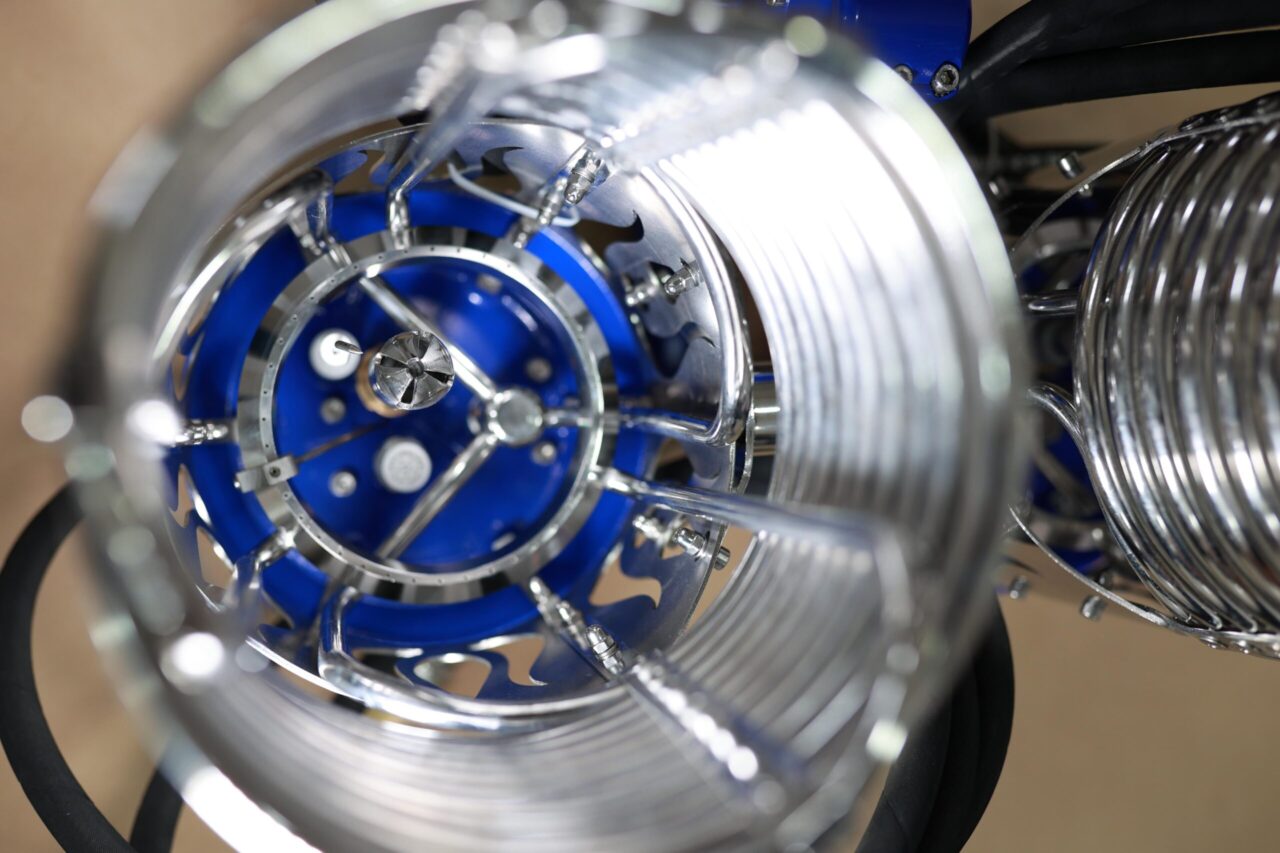

Hot air balloon flight is a delicate balance of design, aerodynamics, and thermal control. At the heart of this equilibrium lies one critical component: the burner. Often referred to as the "engine" of a hot air balloon, the burner directly impacts the balloon’s responsiveness, altitude control, fuel efficiency, and overall safety. At Pasha Balloons, our burner systems are engineered for peak performance and reliability in the most demanding flight conditions.

Understanding the Function of the Burner

The burner system serves a single but essential purpose: to heat the air inside the envelope, causing the balloon to rise. It does this by combusting liquid propane into a high-temperature flame directed upward into the envelope. As the air heats, it becomes less dense than the cooler air outside, generating lift.

However, this process is more complex than it seems. The burner must provide precise and immediate heat output, especially during takeoff, altitude adjustments, and landing maneuvers.

Key Features of a High-Performance BurnerAt Pasha Balloons, we focus on the following attributes to ensure superior burner performance:

Instant Flame Response: The burner must deliver rapid flame output when triggered, enabling pilots to make quick adjustments.

Consistent Pressure and Flame Stability: High-altitude flights require stable performance regardless of external conditions such as temperature or wind.

Fuel Efficiency: Modern burner designs optimize fuel consumption, extending flight time without compromising power.

Redundancy and Safety: Dual or triple burner configurations are often preferred for added security, especially in commercial operations. Each system includes safety features such as shut-off valves, pilot lights, and fuel pressure regulators.

Burners can be single, dual, or triple depending on the size of the balloon and its intended use. For larger envelopes or heavier payloads, multiple burners offer greater control and power. Our engineering team customizes burner configurations to match the specific needs of our clients, from leisure pilots to professional operators.

Impact on Flight PerformanceA well-designed burner directly influences:

Rate of Ascent and Descent: The speed and precision with which a balloon can climb or descend depends on the burner’s responsiveness.

Stability in Variable Conditions: Effective burners allow for finer altitude control in turbulent or thermally active air.

Passenger Experience: Smooth and controlled heating improves ride comfort and enhances safety.

Maintenance and Reliability

Burners are subjected to high heat, pressure, and vibration. That’s why durability is non-negotiable. At Pasha Balloons, every burner system undergoes rigorous testing and is built with aviation-grade stainless steel and precision components. Regular maintenance protocols ensure ongoing safety and optimal functionality throughout the system’s lifespan.

The burner is not just a component—it is the core driver of hot air balloon performance. Whether ensuring a gentle takeoff, maintaining stable flight, or executing a smooth landing, a reliable burner system makes all the difference. At Pasha Balloons, we design and manufacture burners that meet the highest international standards—offering pilots around the world the confidence to soar higher, safer, and smarter.